EADS

The outstanding application of laser processing technology in the aerospace industry can be regarded as the core driving force for the industry to move towards high performance, lightweight, long lifespan, rapid iteration, and cost optimization. In the manufacturing of aerospace engines, ultrafast laser technology is widely used for the machining of gas film holes in turbine blades, cooling holes in combustion chamber liners, and precision machining of irregular grooves. These applications not only improve machining accuracy, but also significantly extend the service life of engine components. Ultra fast laser technology, with its high precision, no thermal damage, and flexibility, has broad application prospects in the aerospace field. In the future, with further development and optimization of technology, ultrafast lasers are expected to play an important role in more high-end manufacturing fields

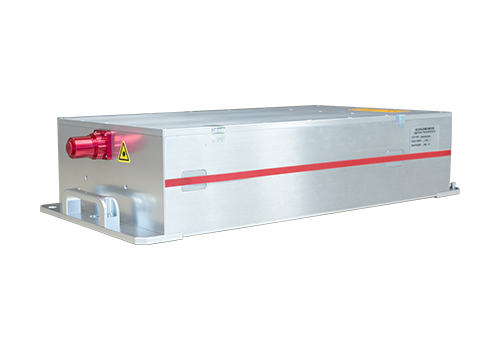

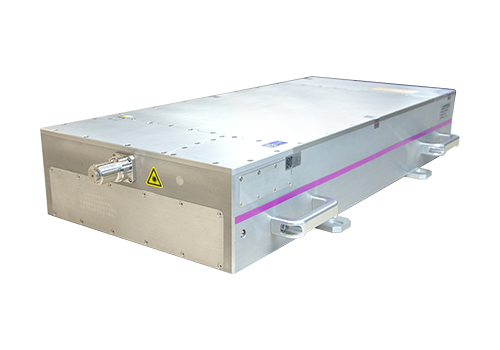

The Shenglei Hercules infrared femtosecond laser series can be used for drilling air film holes and fuel injectors in aviation blades; High single pulse energy and energy stability ensure processing efficiency and consistency.

|

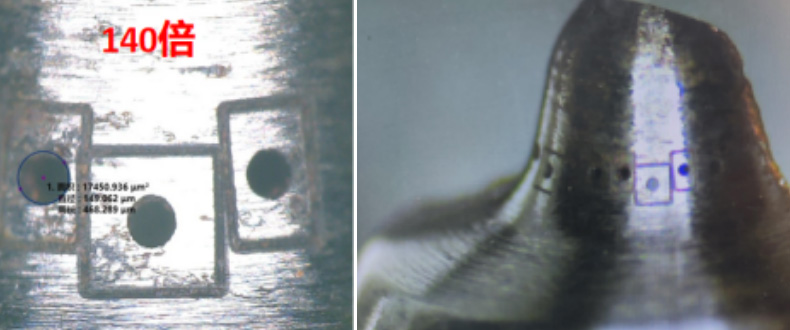

Figure 1 Microscopic View of Aircraft Blade Drilling |

Figure 3 Microscopic diagram of fuel injector drilling |

|

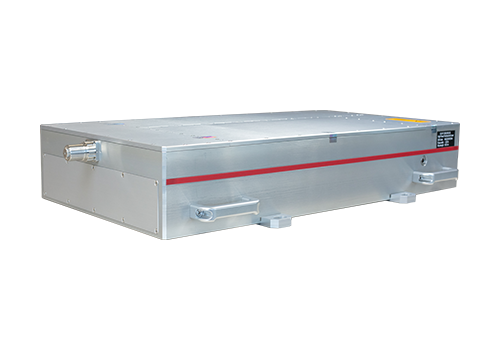

Figure 2: Outline drawing of aviation blades |

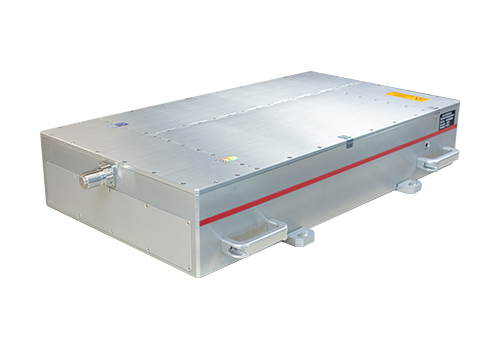

Figure 4: Outline drawing of fuel injector |

Related Products