Brittle Material

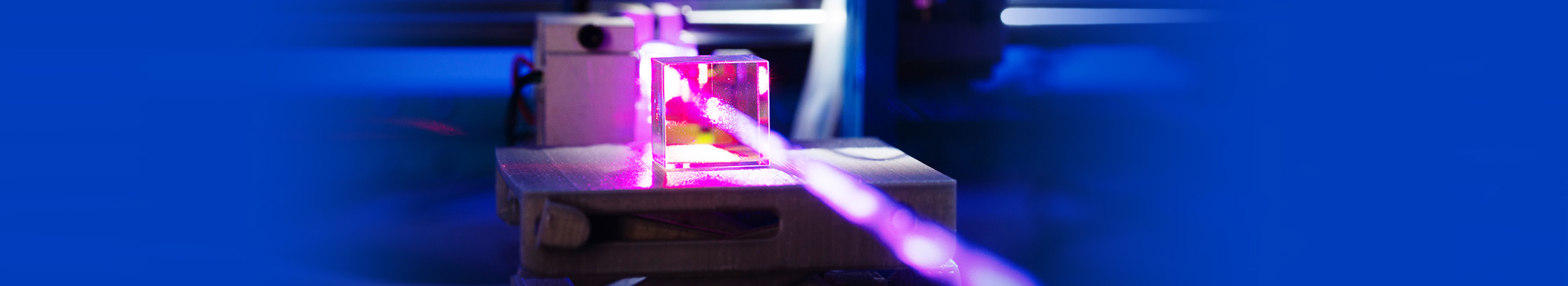

Ultrafast lasers are particularly suitable for processing brittle materials such as sapphire, glass, and ceramics due to their ultra short pulse width and ultra-high peak power. When processing brittle materials, laser energy is highly concentrated in the processing area, significantly reducing heat transfer and accumulation, thereby effectively avoiding cracking and crushing problems caused by thermal damage and stress. The non-contact processing method further reduces the risk of material damage and deformation, ensuring high precision and efficiency in processing. Picosecond laser technology has significant advantages in brittle material processing. Its cold processing characteristics, high precision, and non-contact processing methods make it an ideal choice for brittle material processing, opening up new avenues for fine processing of brittle materials.

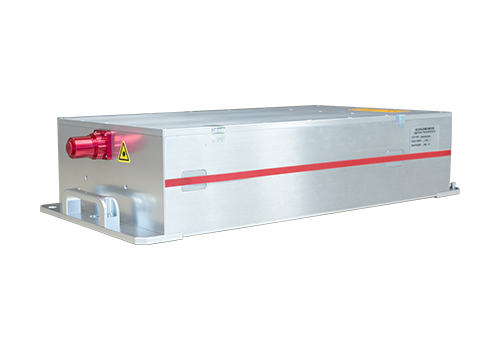

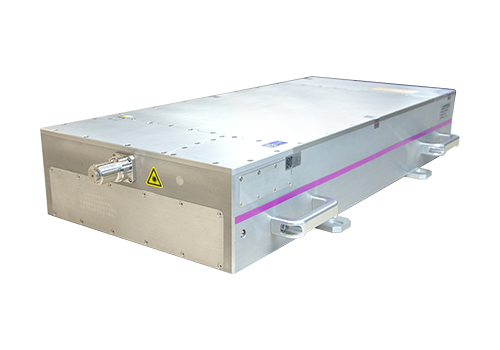

The high-energy infrared and green laser series of Shenglei Leonis picosecond can be used for cutting brittle materials such as glass, sapphire, quartz, and filters, as well as drilling soft and hard ceramics. A 4mJ infrared picosecond laser can cut ultra white glass with a thickness exceeding 22mm, while a high-energy green picosecond laser can cut colored or coated brittle materials with a thickness range of 0.1-8mm.

|

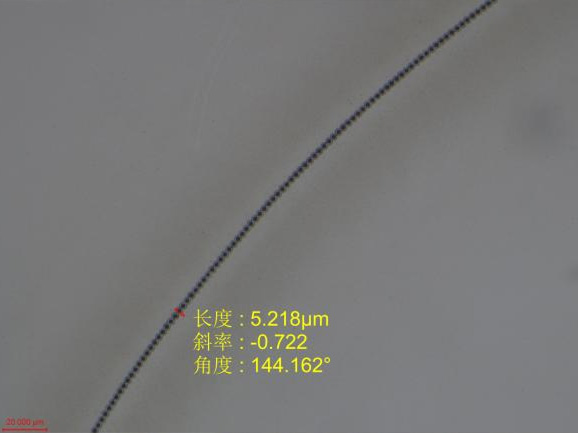

Figure 1 Microscopic image of glass cutting |

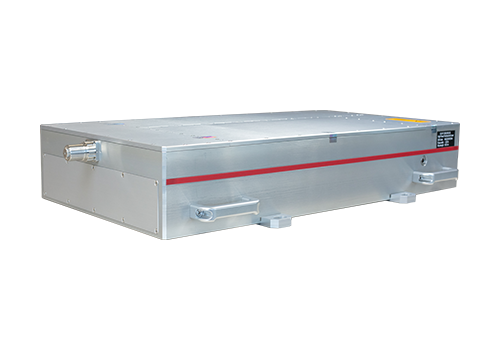

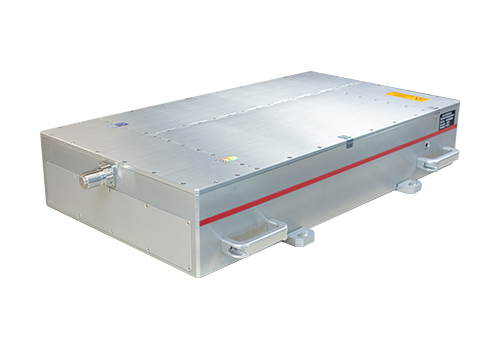

Figure 2: Outline of Glass Cutting |

Related Products